Liquid-immersed distribution transformers

Liquid-immersed distribution transformers

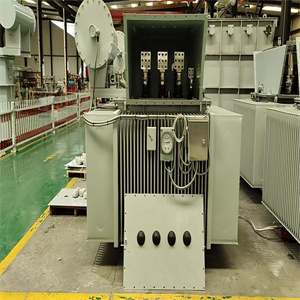

Liquid-immersed distribution transformers use oil as the insulating medium, which has high insulating properties. This can effectively prevent electrical faults and reduce the probability of accidents. At the same time, the oil medium can also absorb part of the heat, reduce the temperature of the winding, and improve the service life of the transformer.

The heat dissipation performance of liquid-immersed distribution transformers is better than that of dry-type distribution transformers. This is because the oil medium has a better heat conduction performance, which can quickly transfer the heat from the windings and core to the radiator, thus reducing the temperature of the transformer. In addition, the design of the radiator also makes the liquid-immersed distribution transformer have a larger heat dissipation area, which further improves the heat dissipation effect.

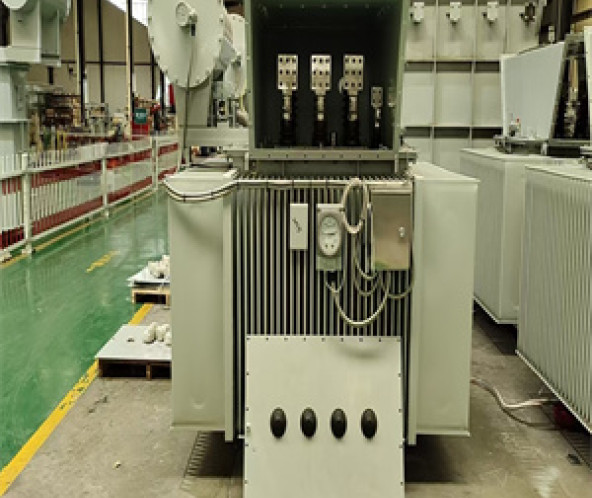

Liquid-immersed distribution transformer details

The main structure of liquid-immersed distribution transformer includes core, windings, oil tank, radiator and so on. Its working principle is to utilize oil as cooling and insulating medium to convert the electric energy on the high voltage side to the electric energy on the low voltage side. Liquid-immersed distribution transformers have higher insulation and heat dissipation performance.

The working principle of liquid-immersed distribution transformer is mainly based on electromagnetic induction. When the AC current on the high voltage side passes through the windings, it generates a magnetic field in the iron core. Due to the magnetic field, an induced electromotive force is generated in the windings, thus realizing the conversion of electric energy. At the same time, the action of the oil medium makes the winding and the core well cooled and insulated.

Related News

Submitted successfully

We will contact you as soon as possible